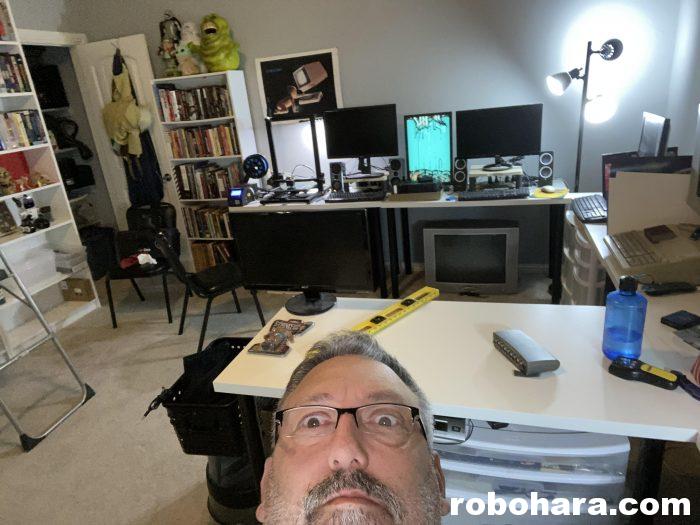

Last month I didn’t know anything about 3D printers, but the universe has a unique way of telling me when it’s time for a new toy. My friend Justin mentioned he could use something 3D printed. Then my friend Jeff also mentioned 3D printing. A blogger I follow, Rob Cockerham, bought a 3D printer. Then I bought a couple of 3D-printed Star Wars-related items online (you’ll have to wait until Wednesday to see those.) After recently selling my car I ended up with some spare money sitting in my bank account, and decided to take the hint from the cosmos and spend some of it on a new 3D printer.

What follows are a few questions I had about 3D printers, and the answers I have learned.

What exactly is a 3D printer?

A 3D printer is a device that prints objects in three dimensions. Instead of ink, it uses filament. The filament melts and turns into itsy-bitsy dots that stick together. In a way, it’s almost like a super accurate, computer-controlled hot glue gun.

Are the printers expensive?

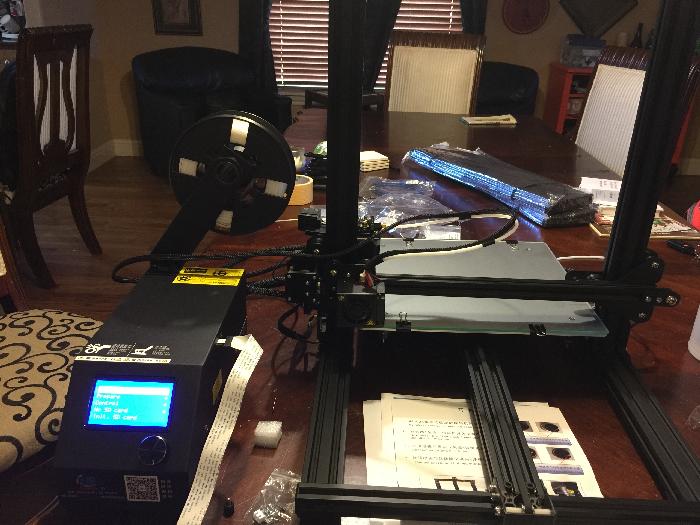

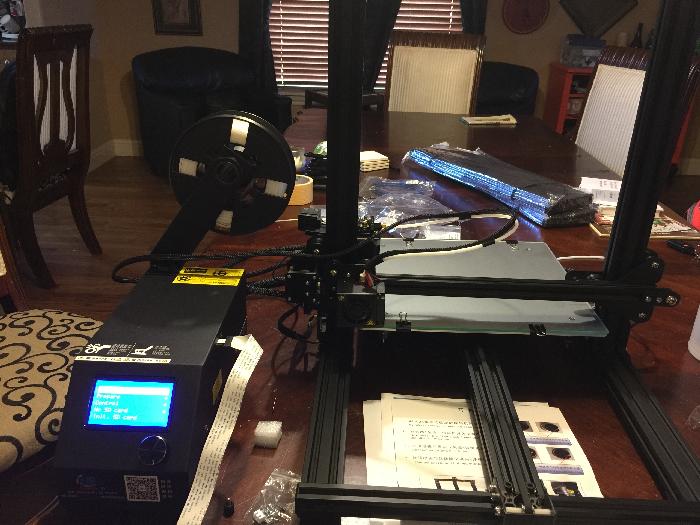

My printer, the Creality CR10s, sells for $599. There are cheaper ones and ones that are a lot more expensive. (The first one I looked at was $4k.) Prices vary based on quality, size, and speed. Some printers can print two colors at once (most can only print one). Some printers have huge online support groups while others do not. I’m not advocating Creality printers one way or the other yet, as I haven’t had mine long enough to form an opinion yet.

Is the filament expensive? How much do things cost to print?

The first part of this question is simple. Rolls of PLA filament cost around $20 per kilogram. They come in a rainbow of colors. The answer to the second question is, “it depends.” Small things that are hollow obviously take less filament than big things that are solid. Before printing, the software gives you an estimate of how much filament your print will require.

How big is the printer? How big can it print?

The Creality CR10s has a print area of 300mm x 300mm x 400mm. That’s slightly less than 12″x12″x18″. (I should warn you that everything related to this printer is done in the metric system.) The printer itself is roughly 2′ tall and, including the controller box, about 2′ wide.

Is it fast?.

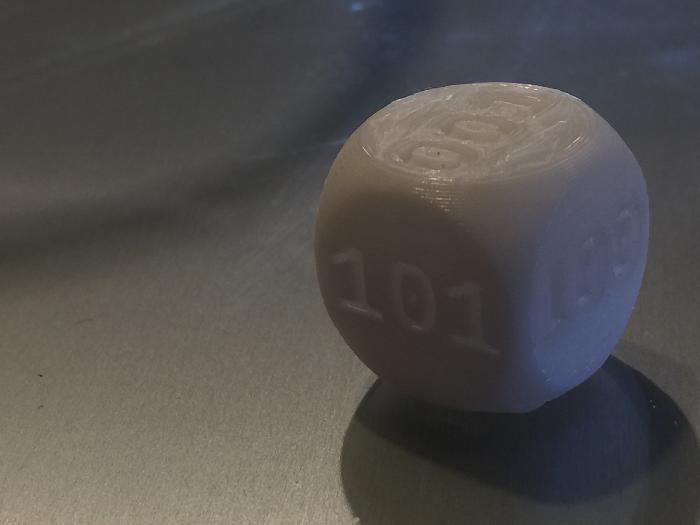

No. Printing something the size of a regular die took 15 minutes. Printing something the size of your fist might take 2-3 hours. Based on what I’ve read, it is not unusual for large prints to take 24 hours or more. Unless you like hearing internal fans blowing and tiny motors going “weee-weee-whirr-whirr” all night long, you might want to put your printer in another room. Because it has a MicroSD slot, the printer doesn’t need to be connected to a computer to print.

Was the printer easy to assemble?

No. The printer came “85% assembled” according to the seller. I watched a video on YouTube where a young lady assembled this same model in 10 minutes. It took me almost 8 hours. I could probably do the next one in 2 hours.

Is it easy to use?

Hmm. Define “easy?” To print something, at a minimum you are going to have to obtain a 3D model of the object somewhere, load it into another program, save that file to a MicroSD card, insert it into the printer, and then hope nothing goes wrong.

What could possibly go wrong?

The temperature of the bed could be too hot. Or too cold. Same goes for the extruder temperature. You could have cheap filament. The print bed might not be sticky enough. The bed might not be level. It might be too high. Or too low. There’s a ton of variables and options that have to be figured out through trial and error.

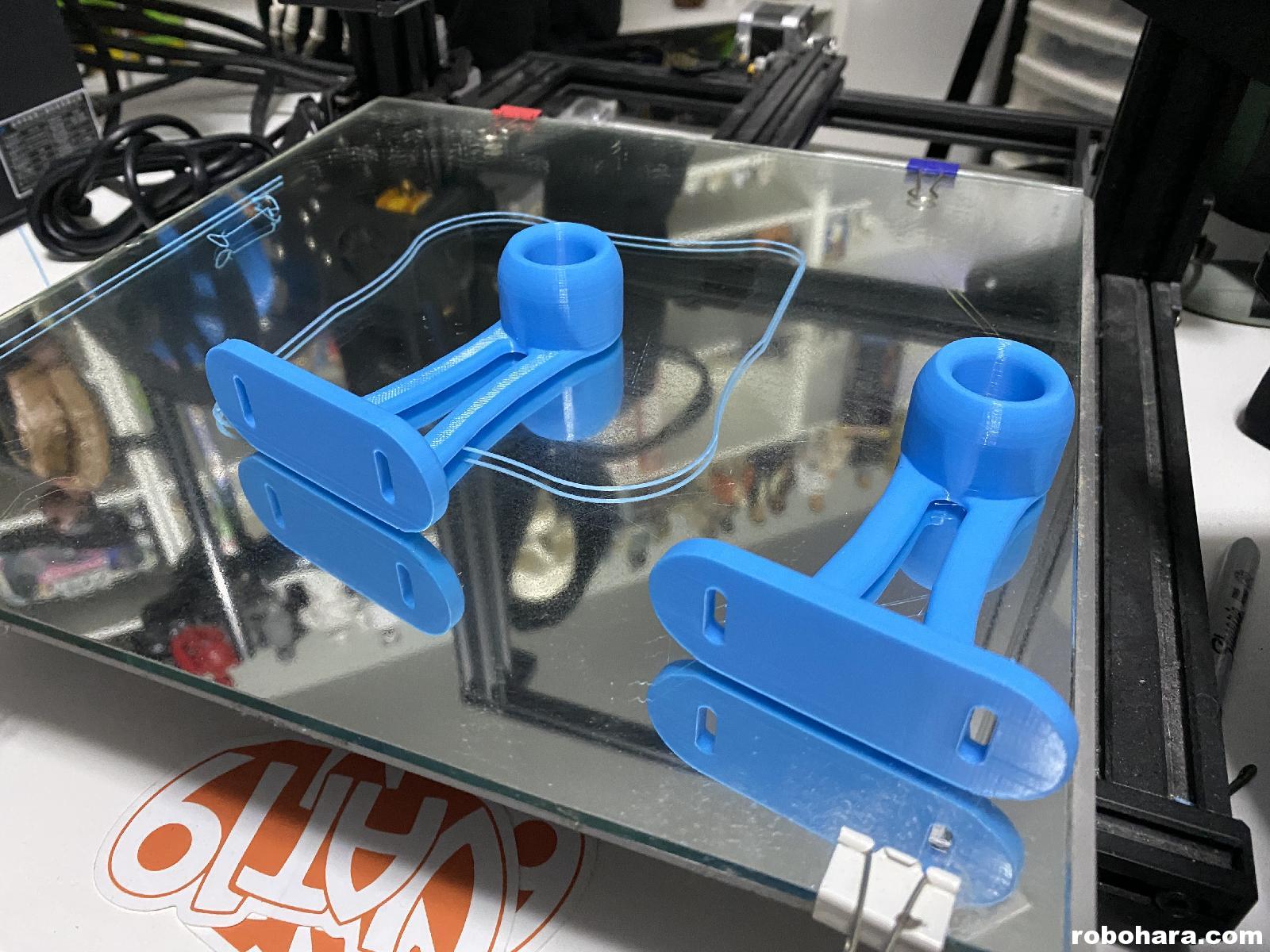

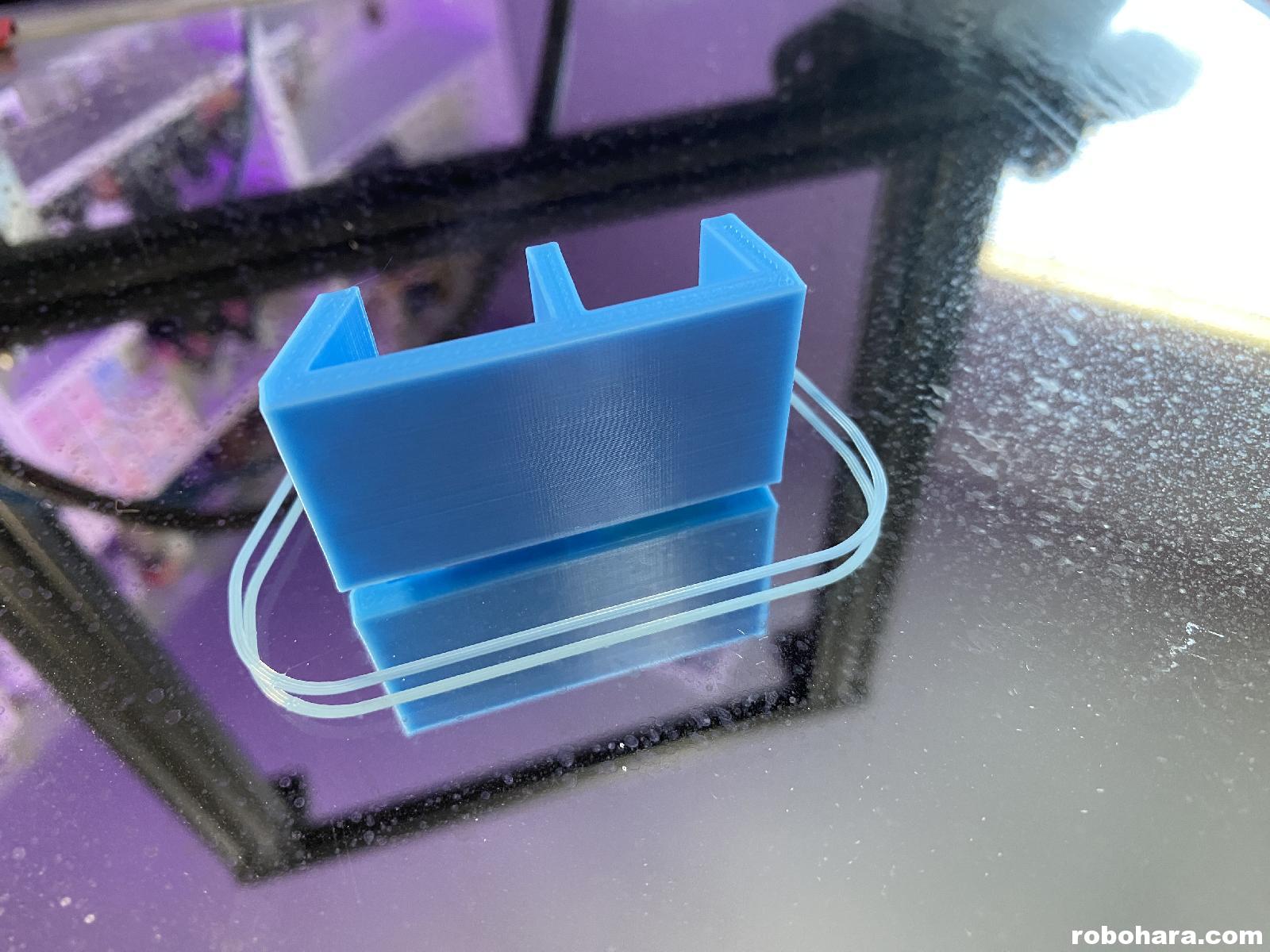

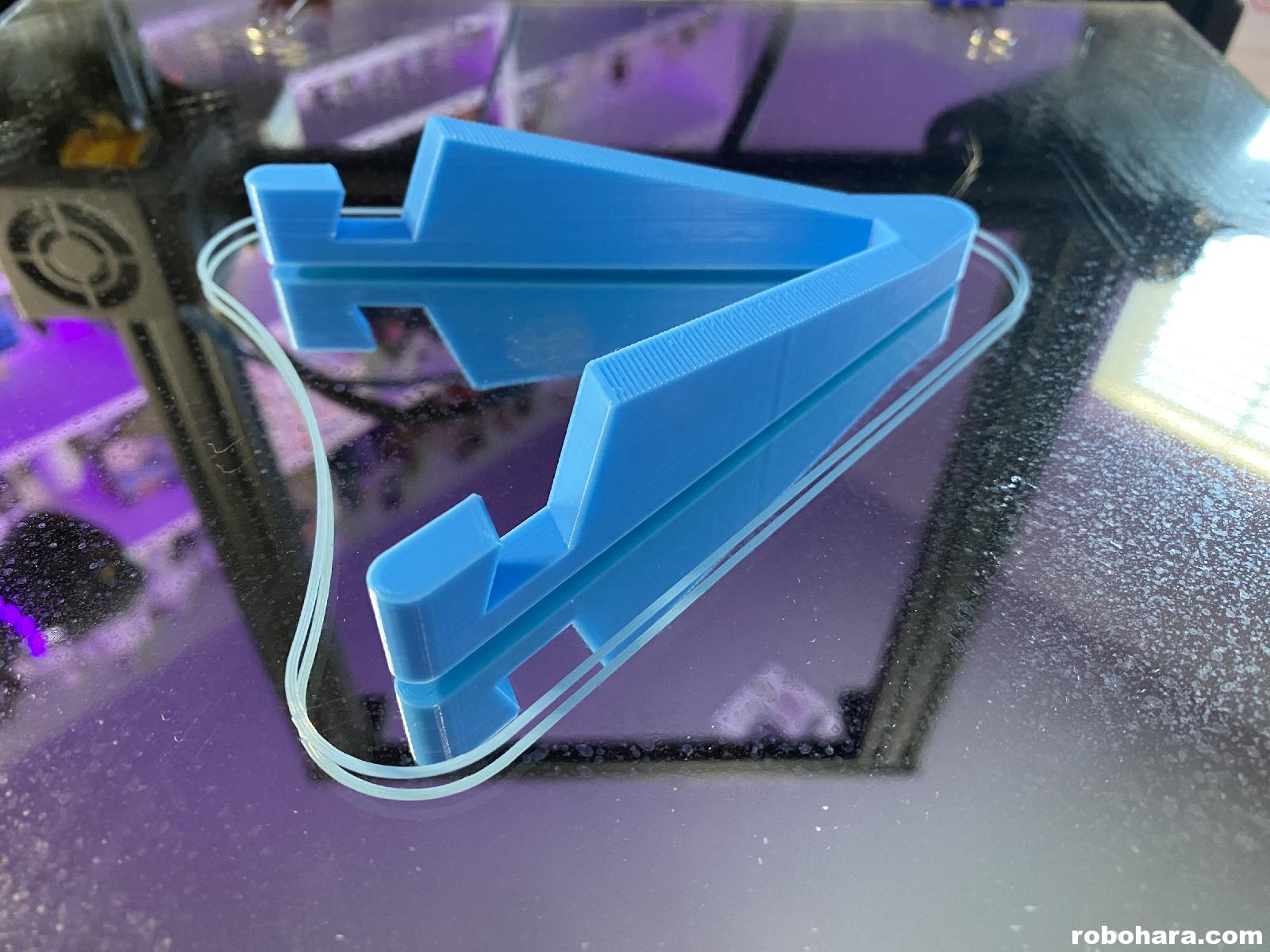

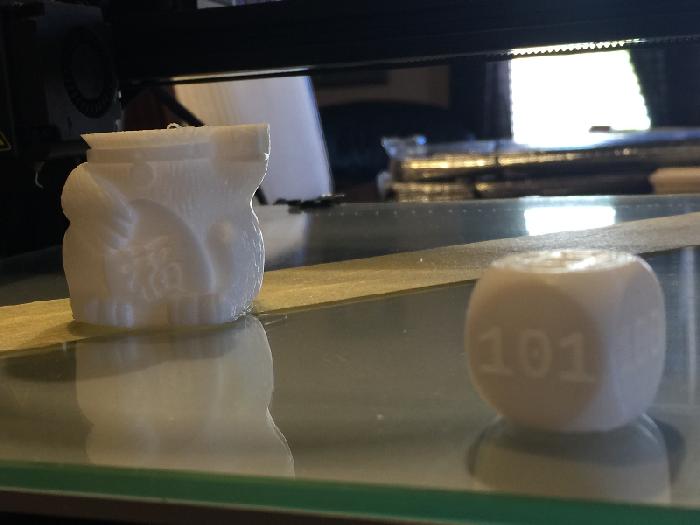

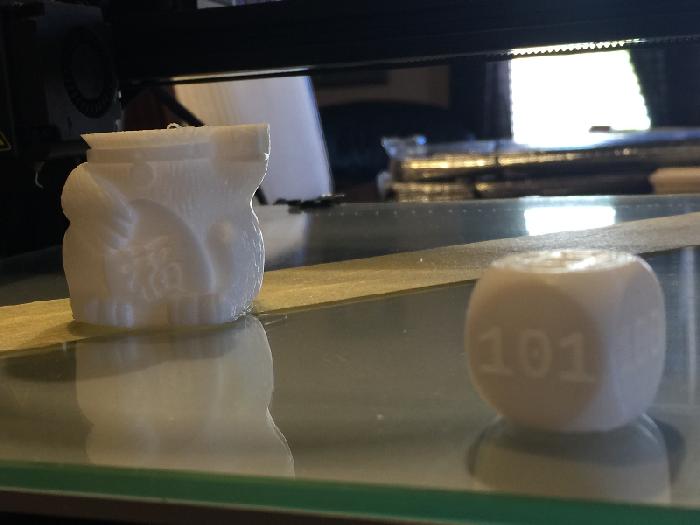

Here are the first two things I printed.

Come on, it can’t be that hard, can it?

Say hello to my new cat on the left, “Headless Harry.”

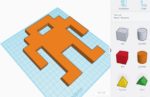

What software is required?

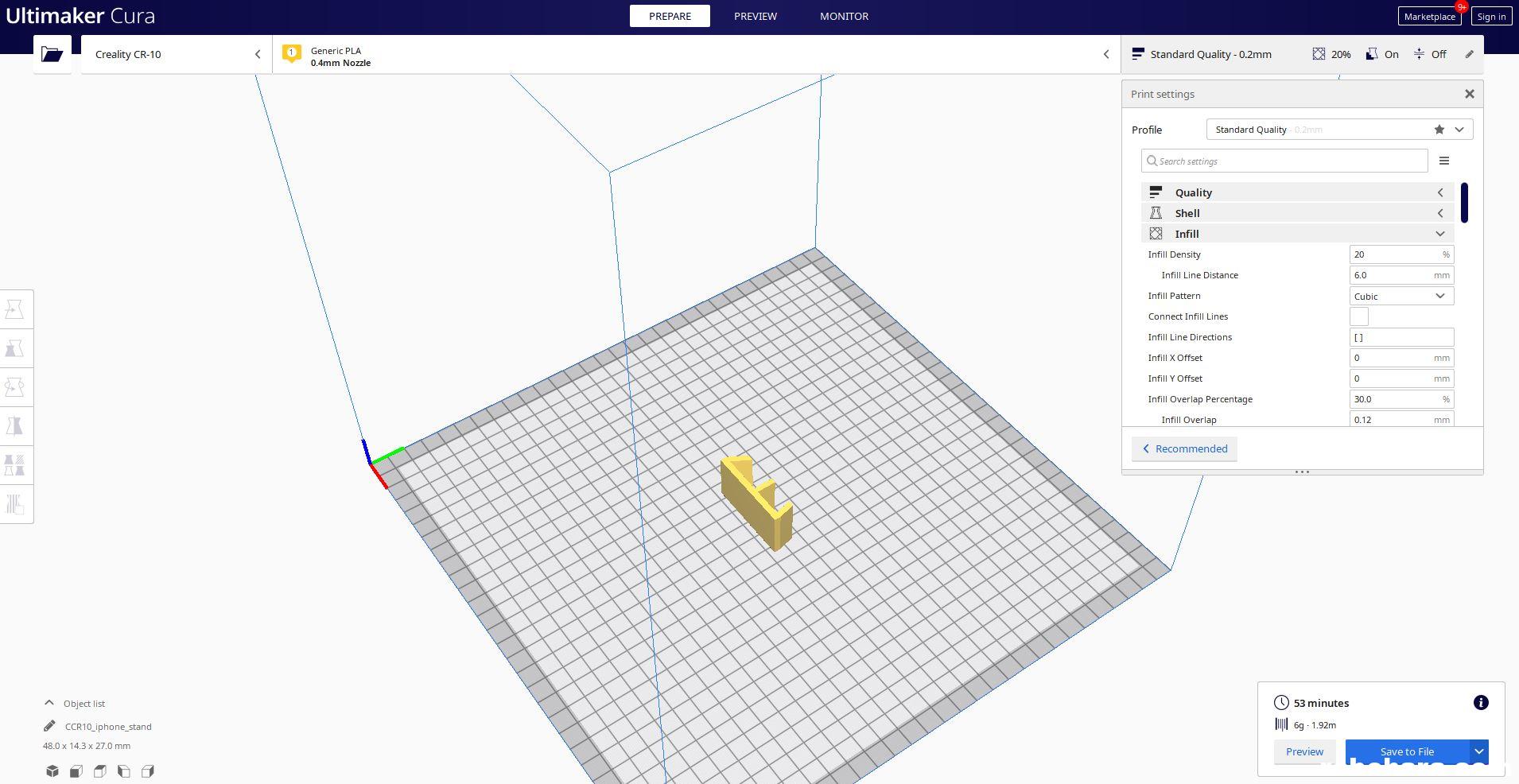

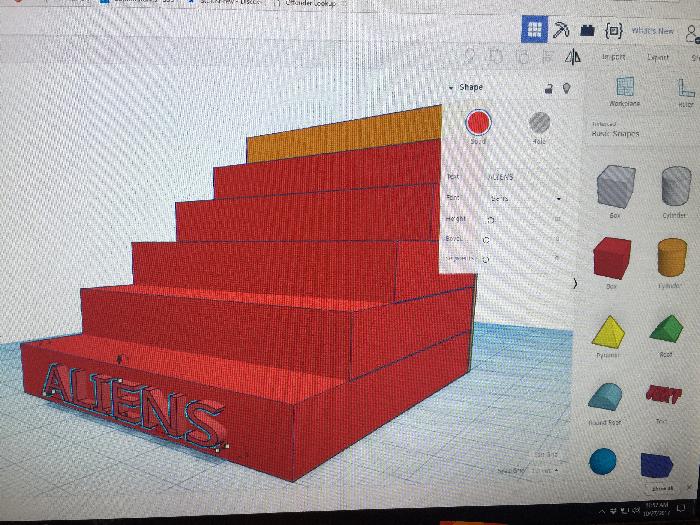

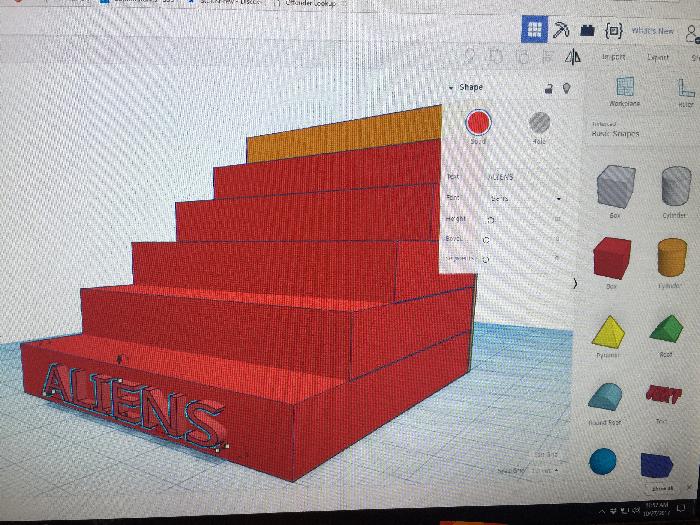

If you want to create your own designs, you can either build them in a CAD program (I’ve been using TinkerCAD) or a 3D sculpting program (haven’t tried that yet). You’ll also need a slicing program, which takes your 3D model and slices it into printable layers that the printer can understand. All of these programs I have used so far are free, and I’ve spent quite a bit of time over the past couple of days learning how to use them.

And finally…

What can I print?

As I mentioned, with a program like TinkerCAD, you can build virtual 3D objects and then print them out. I haven’t actually printed this out yet, but here are some tiny risers I created for some of my collectible figures.

If you don’t feel like learning a CAD program, you’ll want to check out Thingiverse.com, a website with hundreds of thousands of free models available for downloading. Trust me, the people building those models are way better than me. This is a 3D printed version of Rick from Rick and Morty. Note that it didn’t print in color — the person who printed the model also hand-painted it.

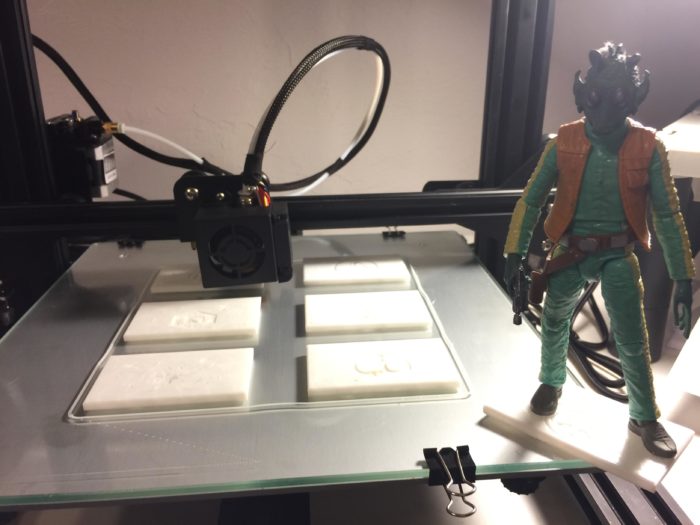

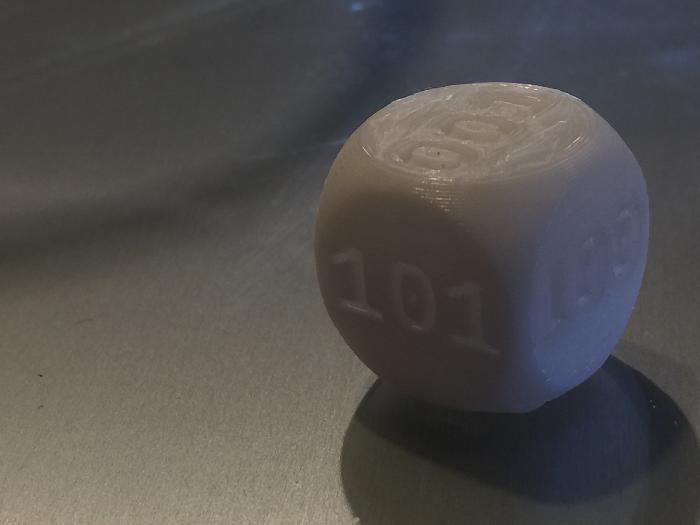

Here’s the first thing I got to print correctly. It’s the Programmer’s Dice from Thingiverse. It’s a six-sided die with binary numbers on the sides. So far I have printed two of them — one for me (which had minor issues), and one for my dad. It’s no headless cat, but eh. I printed this with the white filament that came free with the printer. It would probably look better in a different color.

That’s about it for now. Between work, school, and home life, I know I won’t have as much time to play with it as I would like, but little by little I plan to explore and learn more about it works. I have a few real-life objects I plan to design and print as parts replacements in the future. Maslow said “if all you have is a hammer, everything looks like a nail.” Right now, everything looks like it needs something printed to me!