I recently built a large shelving system for tubs in my garage using only 2x4s. Here is a link to my YouTube video showing exactly how it’s done, followed by a written summary of the process. This is the sturdiest and simplest method I have come up with for adding storage to your garage. If you can cut a 2×4 and use a drill, you can build these.

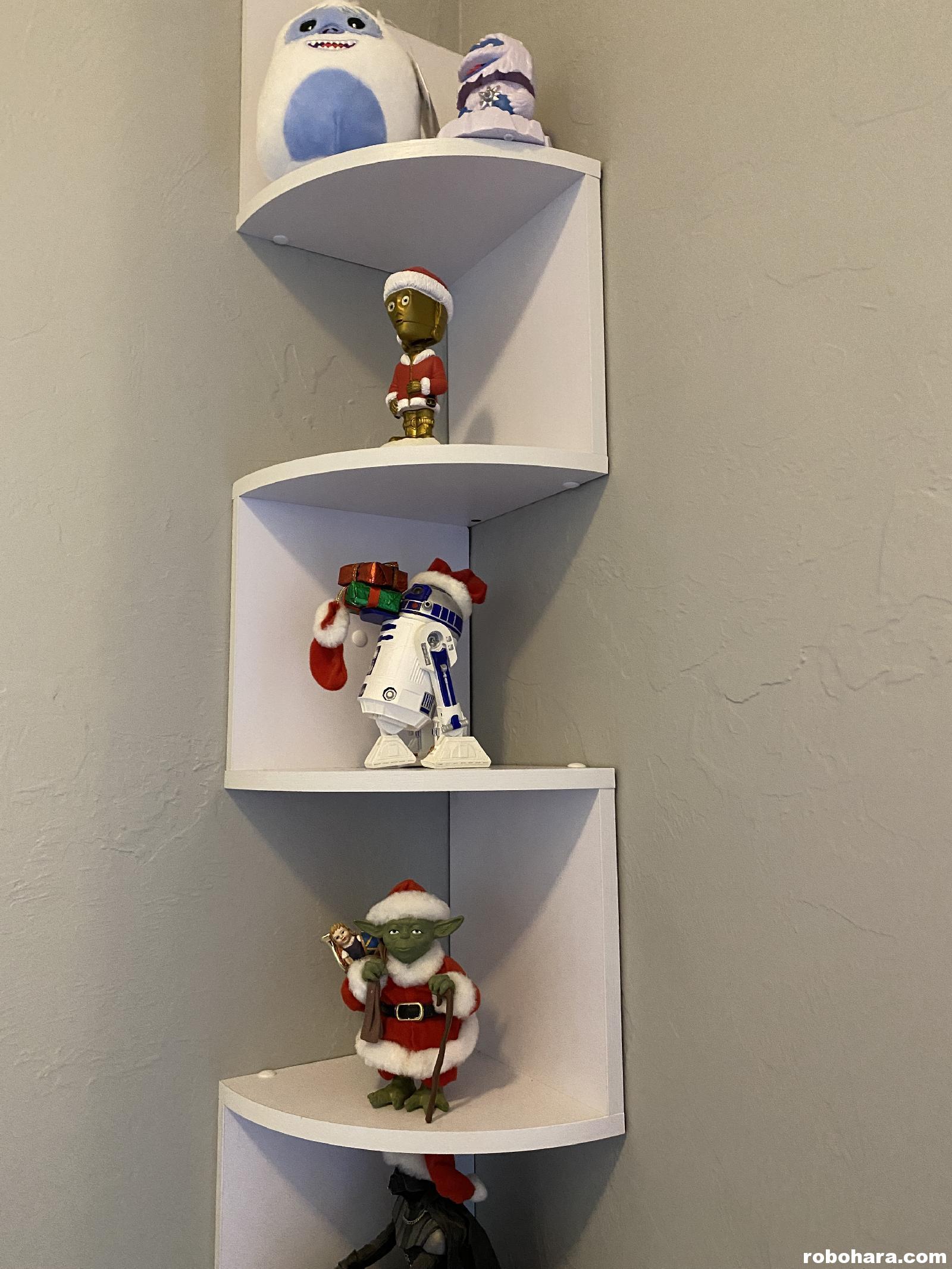

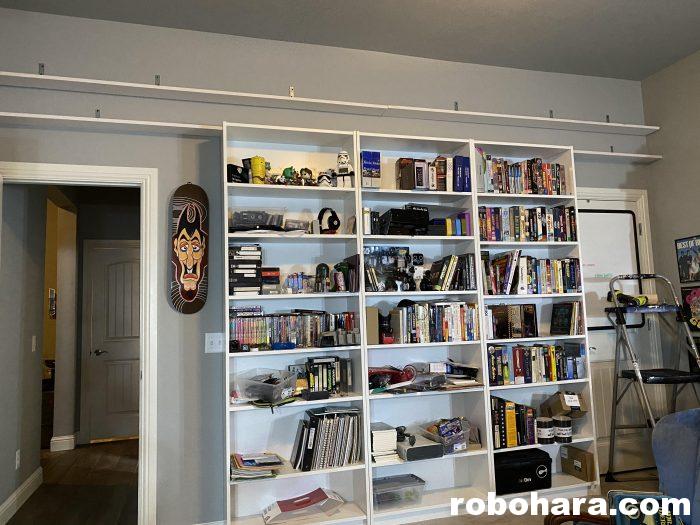

It’s no secret that I love shelves. I love building them and I love putting stuff on them.

When we moved into this house six years ago, I purchased a large amount of Rubbermaid storage tubs to transport and store my large collection of (mostly Star Wars) toys. In our last house I had a dedicated room for my toy display and in this house, I don’t. A lot of the tubs remain in the garage, unopened. I have been slowly parting with some of the toys I only like which is freeing up space in my office for the things I love, but the process is so low on my list of priorities that I fear it may not happen in my lifetime.

The problem with the tubs I purchased is that they don’t hold up to stacking heavier tubs on top. Many of the tubs are starting to cave in, causing the stacks to lean and occasionally topple over. Combine this with all the sourcing Susan has been doing for our toy booth and online sales and I decided a new massive set of garage shelves were in order.

Many years ago I came up with a simple system for building garage shelves that are perfect for storing tubs. My method is super simple. The shelves are made completely from 2x4s and only feature 90-degree cuts. If you can cut a 2×4 and work a drill, you can build these.

Again, I only use 2x4s to build these shelves. Believe it or not, you can easily fit 2x4s in a Ford Flex with the middle seat folded down (and the passenger seat leaned forward just a tad bit…). I am not good at “lumber math” so I bought 24 2x4s which I knew would not be enough, but would be enough to get me started. I built a very similar set of these shelves in a previous home and noted in that article that the 2x4s cost $2/each in 2004. In 2024, I paid $3.50.

Here is how I construct each individual shelf. Every shelf is a rectangular box with one 2×4 on each side and two additional 2x4s in the middle. This shelf is 2′ deep and 3′ side. This is a very cost-effective size because 2x4s are 8′ long, which means you can cut each one into three pieces (two 3′ pieces and one 2′ piece) and build the entire shelf out of two 2x4s. If you’re doing the math, that means each shelf this size costs $7.

The way I build these is very simple. Before starting, I cut a small block of wood that is exactly 6″ wide. That piece of wood is going to be my spacer. After cutting all the other 2x4s to lenghth, I laid the four 3′ pieces parallel and put one 2′ piece on the end. I then drove two 3″ screws into the end of each 2×4. Instead of using a measuring tape I used the 6″ block of wood to keep everything spaced evenly. In other words I screwed the first one onto the end, then put the block in place to line up the second one, screwed that one in place, and worked my way all the way down to the last 2×4. When one side was finished I flipped the whole thing over and did the other side, making sure to start on the same end as before just to make sure all the 2x4s were lined up.

If you watch the video you’ll notice that I started with 2″ long drywall screws, which I quickly determined were not long enough. Driving them through a 2×4 only leaves you 1/2″ of “grip” into the second 2×4, which just isn’t enough. I quickly changed to 3″ screws, and doubled back and drove 3″ screws into all the other joints just to make sure everything was strong.

Once you have a few of these shelves built it’s time to start assembling them.

Again, the key to my system is using spacers. I don’t want to be using a tape measure for every single shelf and even if I did none of them would turn out level. Instead, here is what I do. First, find the biggest “whatever” that you’re going to be putting on your shelves. For these I’ll be putting storage tubs, but I’ve used this same technique to make shelves for CDs and DVDs, too. With your spacer (in this case, a tub) in place, put something on top of the spacer to ensure there’s a gap above it to make things easier to remove. In my case, I used two 2x4s standing on end, one on each end of the tub. With that set up, I then place a shelf on top of that, make sure that it is level, and start screwing the shelf into place. In the above picture (in which I’m installing the second shelf from the ground), I screwed both sides touching the wall into studs. On the outside corner of the shelf I’ve attached a vertical 2×4 and overlapped it so that one half of it is covering the front of the shelf. (We’ll use the other half for the next set of shelves.)

Phone cameras and lenses can be weird so trust me when I say these are more level than they look. Here I’ve added a third shelf. Note I’m using the same technique over and over. Put the tub on the previous shelf, put a couple of spacers on top of the tub, place the next shelf on top of that and then attach it to the studs in the wall and finally the 2×4 in the front corner.

This wall presented some unique challenges, the biggest one being two windows. Had I built another 3′ wide shelf, the end would have landed right in the middle of the window and not given me any place along the wall to anchor it — so I built the next set of shelves to be 6′ wide instead of 3′. This allowed me to attach them to studs on both sides of the window, assuring their strength.

Eagle-eyed readers may noticed I switched tubs. Halfway through the first set of shelves I realized that this green tub was taller than the other one I was using and I wanted to make sure every shelf could hold any tub, so I readjusted the other shelves and switched to this green tub.

Again it really is this simple. Here I’m putting the third (counting up from the bottom) 6′ shelf into place. After building a few out in the driveway I would drag them inside and install a few.

That’s all there is to it! Rinse and repeat until you run out of lumber or run out of wall!

I read on the internet (so it must be true!) that a 2×4 laying flat lenghwise can support 100 pounds, when turned on its side can support 1,000 pounds, and vertically can hold 10,000 pounds. None of these tubs come anywhere near 100 pounds in weight and as you can see, on the 6′ section I am only able to get 4 tubs so there is no way these 2x4s will ever bend from the weight. Not only do the additional 2x4s down the middle of each shelf section add additional weight support, but doing it this way is much less expensive and time consuming than buying a sheet of plywood and cutting it to fit on top of each shelf.

Pro-tip: I didn’t pre-measure how high to make the vertical 2x4s. After the top shelves went on I used a circular saw and chopped them off to be level with the highest shelf.

If you want to turn one of the bays into a temporary shelf, you can easily do it with just a cardboard box folded flat. With all the 2x4s the cardboard won’t sag. I like doing this because I can always pull it back out and make room for more tubs if needed.

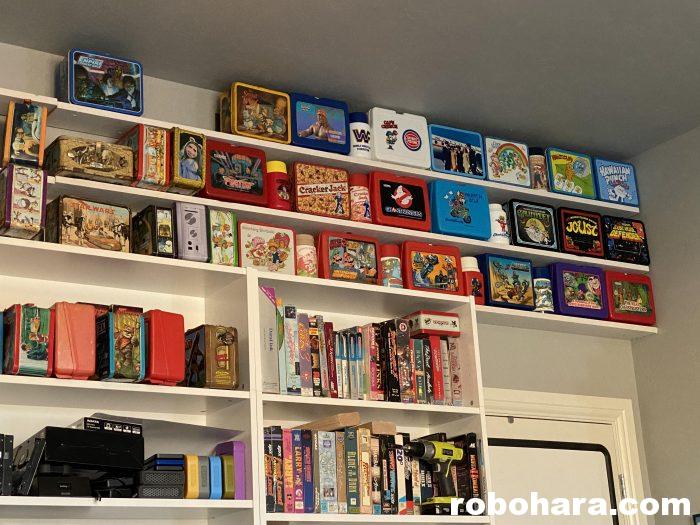

Here is the finished product. The spacing worked out so that I repeated everything twice. Starting at the back corner there’s a 3′ wide section, a 6′ section, another 3′, and another 6′. That’s 18′ in all, plus a 2×4 sideways on the end of each one that adds 3″ (1 1/2″ on each side) for a total length of 19′. My garage is just over 20′ deep, which gives me some space on the end for shovels, brooms and rakes.

You may notice in the above picture that the shelves “stairstep” down a bit — that was to make room for the garage door rails. Again there is not hard set rule as to how high you can make these or how long each section can be.

I hadn’t actually put a pencil to the project to see what it actually cost me, so let’s do that. If a 2×4 currently costs $3.50, that calculates to 43.75 cents a foot — we’ll round up to 45 cents to include tax. After looking at the pictures, here’s what I count:

Seven 6′ shelves with four 2x4s each: (7*6*4 * .45 = $75)

Seven 3′ shelves with four 2x4s each: (7*3*4 * .45 = $38)

Fourteen 2′ end pieces: (14*2 * .45 = $13)

That puts us at $126, so with a few bucks worth of wood screws let’s call it $130. I’m not counting the tools I used.

The closest thing I can find on Home Depot’s website are their yellow steel garage storage shelves, which come with four shelves (one on the ground level) and are 2′ deep (like these), 6′ tall (shorter than these, and provide four shelves. They cost $319 right now (on sale), and you could need at least three sets of them. And if you want to really compare apples to apples, my shelves give me approximately 86′ of shelf storage space for $130. Those Home Depot shelves cost roughly $8.50/foot, so to get the same amount of storage space it would cost you nearly $750. Clearly the shelves I built took a little more effort, but I was able to build them over a weekend, customize the shape and size to take advantage of the space I had available, and save a ton of money in the process.

I am super happy with how these turned out. They cleaned up this entire half of the garage and allow me access to all my tubs!